Why are bolt flanges necessary in exhaust systems?

Bolt flanges are essential components used in exhaust systems. These devices connect two pipes or parts to create a leak-proof seal. They need to withstand high pressure and temperature. This article will give you a brief introduction to bolt flanges. It includes an introduction, tips for welding, and the benefits of titanium bolt flanges.

What are Exhaust Bolt Flanges?

Exhaust bolt flanges connect the exhaust pipe to the exhaust manifold on a vehicle. It consists of two flanges made of metal, such as stainless steel, titanium, and aluminum. It also includes bolts and nuts used to tighten the flanges together. It creates a tight seal to prevent leaks and reduce the risk of damage. 2-bolt flange and 3-bolt flange are commonly used. Exhaust bolt flanges are subjected to high temperatures and harsh environments. So, it is essential to be able to withstand these conditions. Titanium is ideal for exhaust flanges because of its high temperatures and corrosion resistance. This special performance makes it a durable and long-lasting choice. Tifac Parts titanium 2-bolt flange and 3-bolt flanges are designed for exhaust systems. They can be used in high-performance and racing applications. They can help reduce weight and increase strength.

How does the Exhaust Bolt Flange work?

Exhaust bolt flanges use gaskets and bolts to connect them. For easy installation or removal of sections, it is better to use a bolt or V-band flange to set up exhaust pipes. For 2-bolt flanges, we recommend to use an M10 bolt, while an M8 bolt is recommended for 3-bolt option. To ensure the bolts are tightened without breaking, use a grade of 8.8 tensile or higher. Besides, we take measures such as spring washers or locking nuts to avoid vibrating loose.

4 Key Factors to Select Bolt Flanges

When selecting bolt flanges, there are several considerations to keep in mind, including:

- Material: Bolt flanges are available in various materials, such as stainless steel or titanium. The choice will depend on applying temperature, pressure, and corrosion resistance.

- Size: Bolt flanges come in a range of sizes, from small diameters to large diameters. Your size will be determined by the dimensions of the pipes, valves, or fittings you need to connect.

- Pressure Rating: Bolt flanges are rated based on their ability to withstand pressure. The pressure rating you choose will depend on the application's requirements. It would help if you considered the largest pressure and temperature the system will experience.

- Flange Type: There are many exhaust flanges, such as 2-bolt flange, 3-bolt flange, and 4-bolt flanges. Your type will depend on the level of sealing required and matched components.

Tips for Exhaust Flanges Welding

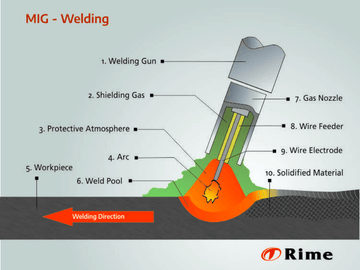

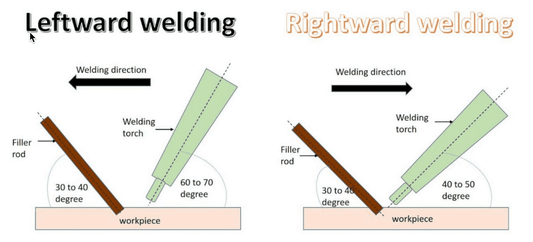

There are two methods to weld exhaust flanges: TIG and MIG. TIG may cause more warping when welding the flange, but the resulting weld will be smaller. MIG welding requires a higher heat input. It is crucial to focus the heat on the flange and allow it to wash over to the pipe. The initial steps involve performing welding at intervals of 20-30mm. It's also recommended to stitch and seam weld the flange, then cool periods between each weld.

Meanwhile, please weld it in quarters and sometimes around the flanges in different directions. You can start at 6 o'clock, run to 9, then 12 to 3, then 6 to 3, then 12 to 9. We do not recommend straightening it with a hammer afterward as it will affect the service life.

Tips and Suggestions

- Creating tack welds every 20-30mm

- Stitch weld the flange

- Bolting another flange to it or a plate twice as thick as the flange

- weld in quarters and do not continuously weld around flanges in the same direction

- Why titanium bolt flanges are essential?

Bolt flanges are widely used to connect the exhaust pipe to the exhaust manifold on a vehicle. They are subjected to high temperatures and harsh environments. So, work under these conditions. Titanium is the ideal material to use in high-performance and racing applications. It can endure high temperatures up to 600°C (1112°F) without losing strength. Make it a durable and long-lasting choice. Especially for racing applications, weight reduction and strength increase are also important factors. Titanium has a high strength-to-weight ratio. They can withstand high pressures without weighing down the exhaust system. This makes titanium ideal for use in vehicle exhaust systems. Besides, titanium bolt exhaust flanges are also easy to machine to tight tolerances. It makes them suitable for use in applications that need precise connections.

Conclusion

Bolt flanges are essential components used in exhaust system applications. They provide a reliable and leak-proof connection between pipes and components. Titanium bolt flanges are strong, durable, and corrosion-resistant options to connect exhaust pipes. They can withstand high temperatures and pressures. They are easy to machine and weld, making them popular in the automotive industry.

No comments

0 comments